Activity content of Technical center

OLIP field of expertiseSupport and procurement for customer’s manufacturing

Activity and business content

Support

- Proposal of method and shape for satisfied function

- Product design, Mold design, Jig design

- Digitalization for trial production process

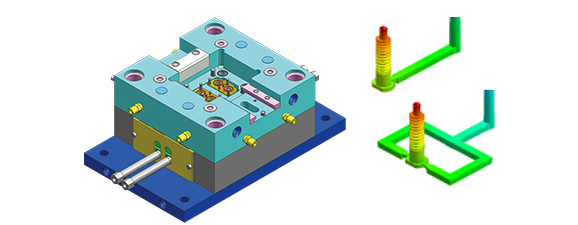

Resin flow analysis for injection molding product ← CAE soft Moldex3D

Curvature deformation measurement for injection molding product and casting ← Non-contact 3D scanner VL300

Thermography measurement when injection molding and casting ← Digital thermography FLIR-CPA-E6XT

For injection molding product, molding condition diversion when transfer from trial to mass production, and validation using equipment above. - VE proposal

Procurement

- Short delivery term trial production

3D printer forming, Casting under vacuum, Cutting (resin, metal)

Simple injection molding, Simple die casting, Sand・Plaster casting - Mold and mold parts

Injection mold, Semiconductor mold cavity, Carbide punch

- Equipment parts

Can making welded products, Cutting process products (speedy and cheaply for small quantity・large variety)

- Overseas procurement including risk management

For example, resin flow analysis for injection molding product

Support case

Design support and resin flow analysis for injection mold

- Proposal of appropriate mold structure that satisfies drawing demand

- Optimization for mold design by comparative analysis

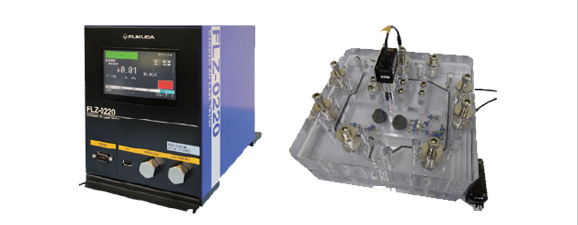

Leak test (Leak jig design・produce ・testing)

- Production and test for simple and low-cost jig

- Provision of test result related to the work

Procurement case

Short delivery term trial product

3D printer forming parts・Casting under vacuum parts ・Cutting process parts

- Provision of 3D printer product high value-added

- Procurement for low-cost and short delivery term trial product

Equipment parts

Can making welded products ・Cutting process products for small quantity ・large variety

- Procurement for equipment parts including painting

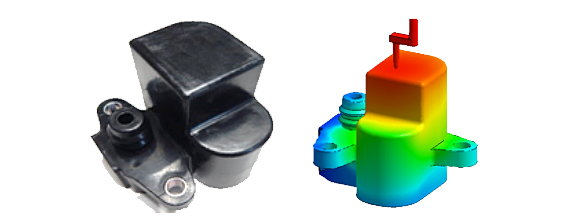

Trial production by simple mold

Simple injection molding products

- Optimization for QCD by overseas procurement

- Optimization for quality by CAE

Simple die casting product

- procurement for low-cost and short term delivery trial product

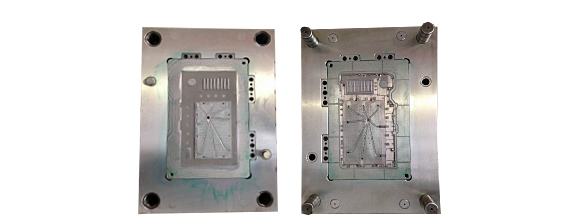

Mold/parts

Injection mold

- Mold that decides the quality of molded item

Semiconductor mold cavity

- Procurement for low-cost and high-quality mold parts

VE case

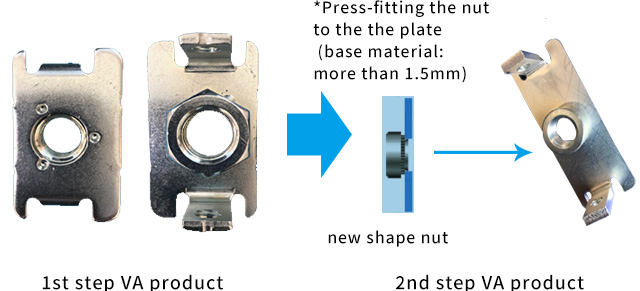

Fixing plate and nut

VE circumstance

- Past method

- Welding whole circumference of hexagon nut on the plate(press product)

- 1st step VA

- Stop welding the whole circumference →Welding the 3 points on the plate with necessary strength

- 2nd step VA

- Welding 3 points → Press fitting new shape nut to the plate

Effect

- Reduction for person-hour

- Being able to press-fitting with plated item

- Being able to fit to M16

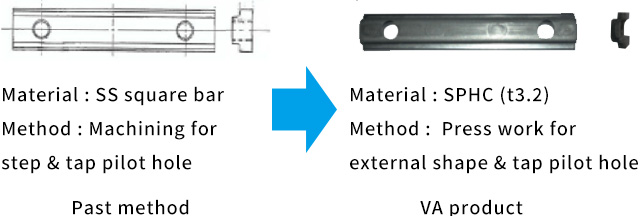

Nut : machining → press work

VA circumstance

- Past method

- Production by machining

- VA

- External shape production by heading and press work + machining (only thread)

Effect

- Reduction for person-hour

- Reduction for material

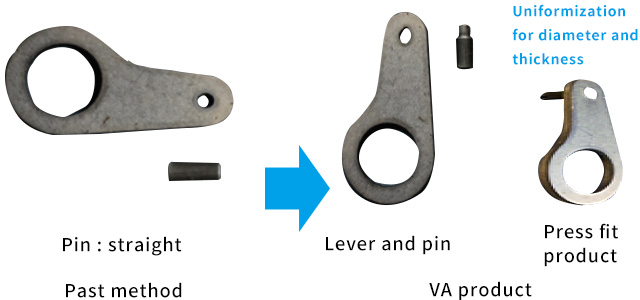

Fixing lever and pin

VA circumstance

- Past method

- Welding the lever and the pin. Inserting the straight pin to the lever hole. Welding the backside.

- VA

- Press fitting the lever and the pin

- Improving the shape to the hole and the stepped pin

Effect

- Reduction for person-hour

- improving the fixing of lever and pin

- Reduction for person-hour of process maker